Whether it’s boxes being loaded onto a delivery truck, suitcases being squeezed into the cargo hold of a passenger plane or shipping containers being stacked carefully on a vessel, weight is a critical factor. The weight of cargo in any form of transportation has significant impacts on the safety, efficiency and sustainability of each trip. The best way to achieve a safe and sustainable truck load is properly balancing the cargo, which is achievable with the use of weighing scales.

What is a Balanced Load?

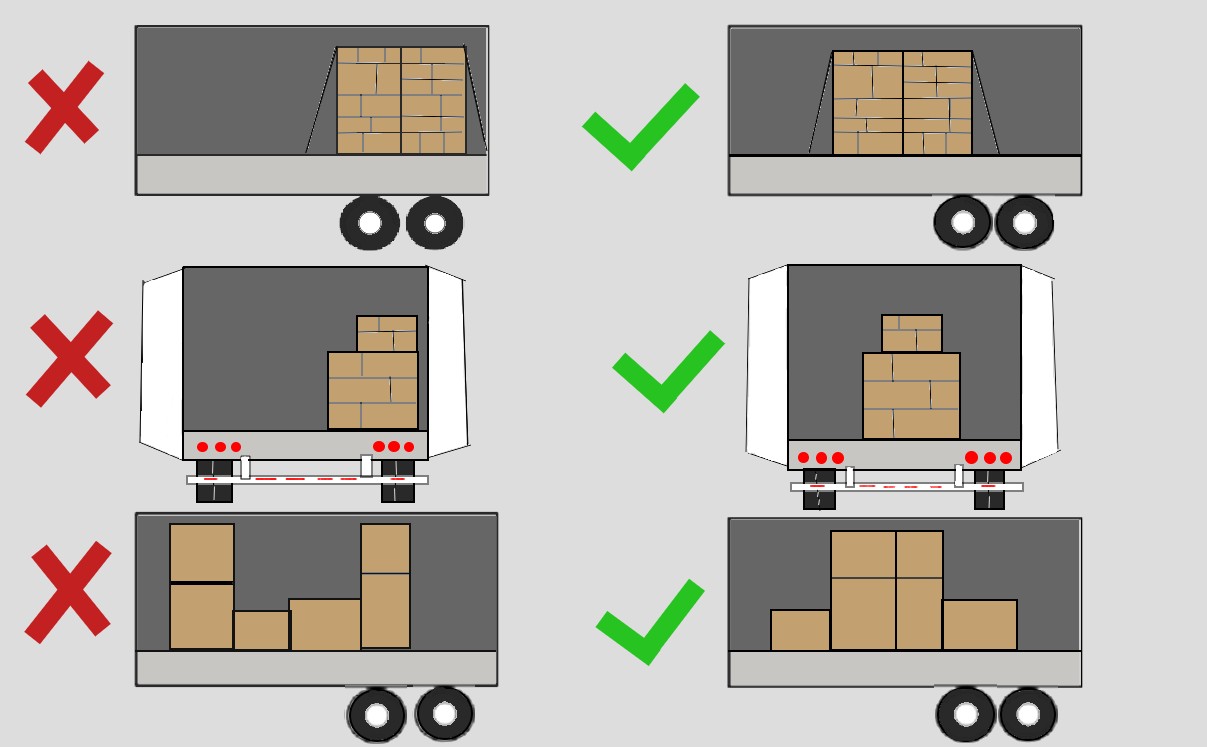

You can achieve a safe, balanced truck load by organising cargo so that the weight is distributed evenly throughout the vehicle. No one side or area should be heavier than another. Make sure to include the weight of the vehicle itself, in addition to the weight of any passengers while organising. This way, you can determine the proper centre of gravity (where most of the vehicle’s weight is stored) and concentrate the heaviest items there.

Common Mistakes Leading to Unbalanced Loads

Three mistakes can cause an unbalanced load. The first is having a load that exceeds the weight capacity of the vehicle in general, no matter how evenly distributed. The second is having a load that may be under the weight capacity, but the heaviest items are arranged in a way that disrupts the centre of gravity. For example, the centre of gravity on the typical truck is towards the middle. The heaviest items should be loaded into the middle of the truck, with lighter items surrounding it.

The third mistake is properly arranging the cargo, so it’s distributed evenly and is well balanced, but failing to secure the load. Should the cargo slide, such as if a cargo ship hits a large wave during a storm, operators may not be able to fix it in time and it could have dangerous consequences.

Why Does Load Balance Matter?

There are a multitude of potential consequences that could occur with an unbalanced load. Have you ever seen someone try to get on a canoe, lean over too far and end up in the water? Without optimised cargo placement, quick turns or stops can result in a tipped over truck and a sinking ship. Best case scenario, you’ll just end up spending a lot of money to repair or replace your vehicle as well as replacing the cargo. Worst case scenario, bystanders and operators suffer injuries.

Those are more obvious and immediate consequences of unbalanced loads. There are also some that become increasingly serious over time, such as the environmental impact.

Increased Fuel Consumption and Elevated Emissions

The heavier the load, the harder the engine of the vehicle must work to compensate and propel itself forward. You’ll find yourself stopping to refuel more frequently as it burns faster. Burned fuel contributes carbon dioxide (CO2) into the air, via exhaust. CO2, along with a variety of other pollutants, is classified as a greenhouse gas. Greenhouse gases keep heat from escaping our atmosphere, warming the planet and causing many serious issues.

According to the United States Environmental Protection Agency, the transportation sector was responsible for 28% of total U.S. Greenhouse Gas Emissions in 2021, beating out the agriculture, commercial & residential, industry and electric power economic sectors. Within the transportation sector, more than 90% of the greenhouse gas emissions are a result of burned gasoline and diesel fuel.

Increased Waste

Unbalanced trucks or ships are more likely to crash, sink, or become damaged. Damaged cargo written off as trash often ends up in landfills. On the bright side, when a truck crashes, there is the potential to gather and correctly dispose of or recycle the damaged goods because they’re relatively easy to access. In the case of an unbalanced shipping vessel, the cargo may end up at the bottom of the ocean.

According to the World Shipping Council, an average of 1,566 containers are lost at sea each year. This may seem minimal but adds up over time, with approximately 15,660 lost over the last ten years. Unsecured containers often fall into the ocean due to rough waters. Depending on how deep the water is, recovery is expensive or even impossible. Most companies prefer to absorb the loss or write it off, resulting in thousands of sunken shipping containers littering our oceans and impacting ecosystems.

When it comes to damaged vehicles carrying oil or chemicals, toxins that remain after cleanup leach into the water system and soil. This causes a hazard to plants, animals and people. Safe loading prevents this from happening!

Infrastructure and Vehicle Damage

Has your town ever repaved a particularly damaged road, and it’s broken and bumpy again within the year? When unbalanced trucks and cars drive over these roads, they contribute to wear and tear more than balanced trucks. This is because unbalanced loads stress certain areas of the truck, applying more pressure to the road, wearing it down unevenly. As a result, your town repaves those roads more often. The repair process then adds more CO2 to the atmosphere, creating a cycle of environmental impact!

This issue has gotten so prevalent that many U.S. states, like Arizona, Michigan, Connecticut and Washingon, have placed weight limits for trucks travelling in and out. Weigh stations have been installed on main roads entering these states to guarantee that trucks are below the limit, which may vary depending on the number of axles.

Not only do the roads experience an increased rate of wear and tear, but the truck itself does as well. You’ll find that unevenly packed trucks will require brake, tire and wheel replacements more often. Just as the road is experiencing more pressure, so is your main piece of equipment!

Safe truck loads mean less stops for fuel, reducing CO2 emissions, limited waste enters our landfills, and our roads stay smooth for longer.

The Role of Weighing Scales in Arranging Safe Truck Loads

Weight distribution is extremely important, so weighing scales play a key role in balancing truck loads by supplying highly accurate results. Why does this matter?

Consider a situation where someone asks you to transport what you believe to be a 15-kilogram box from one end of a warehouse to the other. You reasonably expect to be able to carry that weight yourself without any assistance or preparation. Well, it turns out that this 15-kilogram box is 30 kilograms, and carrying it is much more difficult than you expected. Accurate weight measurements allow you to properly prepare and take precautions. In this situation, you could have brought a hand truck to transport the box instead of carrying it yourself.

Accurate weight measurements therefore help prevent capacity overload. You would be fully aware of the weight of each item being boarded and can pack the vehicle accordingly. It also helps to balance the load, as you’ll know which packages are the heaviest. You can then place them in the most optimised location on the vehicle.

Which Scales are Used for the Job?

Corporations and businesses regularly oversee pallet shipments. In this case a pallet truck scale such as the PTSplus or our AELP Pallet Beams are suitable. For extremely large or unusually sized shipments like a container, you need two forms of weighing. First, the shipping containers themselves need to be balanced inside, so you should pack each item according to weight. Once you finish loading the items, weigh the whole container so you know the total. This is done with a crane or hanging scale like the IHS, which can handle up to 10,000 kilograms. After you know this weight, you can place the container on the vessel in the right location.

You may have noticed that whenever you ship a parcel, the clerk weighs it on a shipping scale. This is often a floor or platform scale such as the CPWplus series or the PT Platform. For smaller packages, the clerk may have a bench scale on hand such as the Latitude LBX. The price you pay to ship correlates with the weight of the parcel. The heavier the parcel is, the more money you’ll spend. This is because heavier items need more accommodation. A large parcel may even take the place of multiple smaller items so as not to overload or unbalance the delivery vehicle. This will allow those loading to make the most of the space available, reducing the number of trips necessary and making your supply chain more efficient.

Safe truck loads won’t solve global warming, but by using weighing scales to accurately load and balance goods, you can help make the transportation industry more sustainable. If you have any questions about which scale is right for you, contact us for help.